- Monday - Friday 08:00-17:00

- 7117 Q St, Omaha, NE 68117, US

- 402-331-6311

- 7117 Q St, Omaha, NE 68117, US

- 402-331-6311

Vanair’s line of engine driven systems delivers rugged, heavy duty, reliable and efficient solutions to meet our customers’ compressor’s air needs. Offering 80-260 CFM of air, with up to 175 PSI, Vanair engine driven systems are built to meet the challenges of robust applications such as pavement breaking, boring, monument engraving, and general air tools. Available with gasoline or diesel engines, and rotary screw or reciprocating air ends, these systems are made to provide the utmost in portability and fuel savings. Whatever your challenge, Vanair® has a solution.

Vanair’s line of entry level reciprocating compressor packages were developed to meet the demands of customers that need the convenience of mobile air at an economical cost. Designed to provide rugged, powerful, and dependable performance, these compressors are a perfect fit for the mechanic, service, agriculture, and contractor markets. The Vanair® PRO Series offers Honda® or Kohler® engines and air power from 18 or 35 CFM with up to 175 PSI. Systems are all electric start and are available in a skid, 10-gallon twin and 30-gallon tank configuration.

Rugged, dependable, and easily transportable, the Vanair’s Contractor provides you with 20 CFM of air power and 5 kW of peak AC generator power for all your tough jobsite needs. Available with a control panel on the unit with two outlets or a remote mountable control panel for easy access.

The redesigned Viper™ Gas Rotary Screw Air Compressor allows you to get in and out of the job site fast. Featuring a larger fuel tank to provide six and half hours of runtime at 70% duty cycle gets you through multiple projects, without having to halt production to refuel. A smaller footprint saves valuable trailer or truck bed space for more tools.

Built to meet the challenges of today’s demanding applications, Vanair’s Viper™ Diesel 80 CFM rotary screw air compressor is tough enough to drive most 90 lb. jackhammers and 1 1/2” impact wrenches. The Viper™ Diesel is equipped with Smart Start Technology™ that senses air demand to reduce fuel consumption, improve efficiency, and increase productivity. Features a EPA certified Tier 4 Final certified field proven Kubota® engine for maximum reliability.

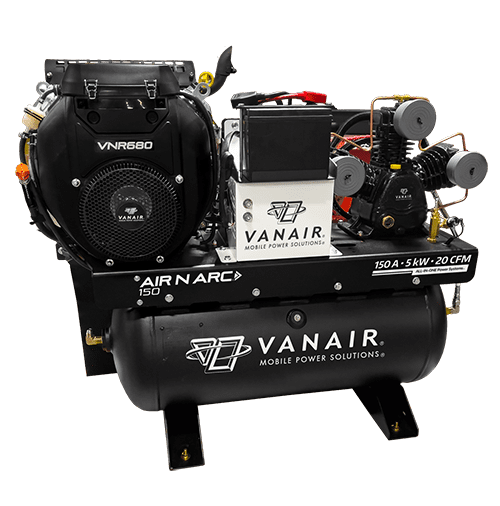

One machine can do it all. The Air N Arc® ALL-IN-ONE Power Systems® provides up to six forms of power in one compact machine. Featuring configurations consisting of a welder, generator, air compressor, battery booster, battery charger and hydraulic output, the Air N Arc® line provides you with a complete mobile workstation on the back of your truck.

The Air N Arc® 150 provides you with five forms of power in one compact and economic unit, allowing you to save space and weight on your vehicle. Providing up to 190 AMPs of welding power, the Air N Arc® 150 is available in three configurations to meet your mounting needs.

The Air N Arc® 250-L features an aluminum reciprocating air end, base, and sheet metal to reduce the weight of a standard steel skid mount system by 30%. The Air N Arc 250-L still offers all the advantages you expect from an ALL-IN-ONE Power System® including five forms of power in a single machine, increased availability of valuable bed space, reduced spending costs on purchasing multiple machines, and reduced truck idle time by turning off the truck. Be ready any time, by having all your necessary power sources on board, all of the time!

The Air N Arc® 300 system, provides more efficient use of your truck bed and reduces cost by combining five power sources: Rotary screw on-demand air compressor, 7 kW generator, 300 AMP welder, battery booster and battery charger – into one single unit. Designed as a true two generator system, the Air N Arc® 300 series allows multi-functioning such as welding and generator for lights for night time service.

While keeping full functionality of five power sources in one unit and the capability of multi-functioning, the Air N Arc® 300 Compact ALL-IN-ONE Power System® was designed to be mounted under a box type body. Coming in 7.5 inches shorter and up to 100 lbs lighter than the standard Air N Arc 300 with fuel tank, the new compact unit provides the flexibility and space-saving capability to mount the unit outside the body of the vehicle while still maintaining ground clearance.

The Air N Arc® 300 Hydraulic ALL–IN-ONE Power System® features the innovation of being hydraulically driven, while still offering all the advantages of the Air N Arc® 300 engine drive system including a 40 CFM rotary screw air compressor, 300 AMP welder, 300 AMP 12V charger and 12V/24V booster, and 7 kW generator.

Vanair’s inclusive, innovative, indispensable Air N Arc® I-300 is the first system in the world to offer six forms of power in a single 48” unit with full multi-functioning capabilities. The Air N Arc® I-300 unique system allows you to turn off the trucks engine and while still supporting the electrical of the truck, so all the emergency lighting can still be used without fear of killing the truck battery.

Releasing December 2023! Vanair®, the leading manufacturer and innovator of Mobile Power Solutions® and Lincoln Electric®, renowned for its world-leading design, development, and manufacturer of arc welding products, have joined forces in a strategic collaboration that leverages the strengths of both companies to bring the next generation of Air N Arc® ALL-IN-ONE Power Systems® to the marketplace. The new Air N Arc® 330 Diesel will have 50% more air power, 43% more electric power, improved jump-starting performance, enhanced features, and now dramatically increased multi-process weld capability, all in an attractive, quieter compact package. Automatic start/stop and engine speed control for fuel savings are other enhanced features of the unit.

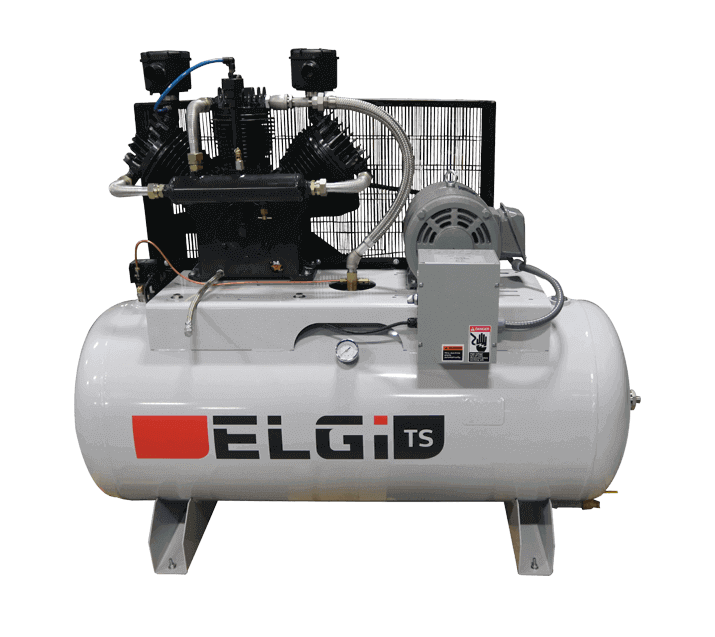

Reciprocating air compressors, also known as piston compressors, are the economical compressor system option ideally suited for intermittent duty cycles. Our durable designs are adaptable for many applications and range from inexpensive .75HP to more rugged industrial models up to 125HP. We carry oil-lubricated, oil-free, and gas driven reciprocating compressor models.

OL Series is the ideal reciprocating oil-less air compressor

(w/ Aftercooler)

(w/ Aftercooler)

(All options)

These “hybrid” compressors offer the durability and 100% duty cycle of a rotary screw, together with the intermittent demand and energy savings of a piston. Under normal operation, the rotary runs continuously, as they are designed to, and the piston automatically runs intermittently when the rotary cannot keep up. If no air is required for 10 minutes, the rotary will also turn off and remain in standby mode until air is required again, providing a seamless supply of air while conserving electricity.

Same features as Industrial Series.

1 PHASE – MOTOR 3450 R.P.M. WITH FULL 15% SERVICE FACTOR & OVERLOAD PROTECTION.

Serving the Midwest since 1990, we pride ourselves on providing our clients with exceptional, professional service.